Import Cortecloud JSON

Who is this import for?

This import is intended for users who want to integrate their systems with Cortecloud by exporting JSON files containing information about parts with drillings and machining.

The JSON must be generated by the partner, following the structure documented here.

Import process steps

The import is available for woodworking professionals through the Cortecloud Desktop application.

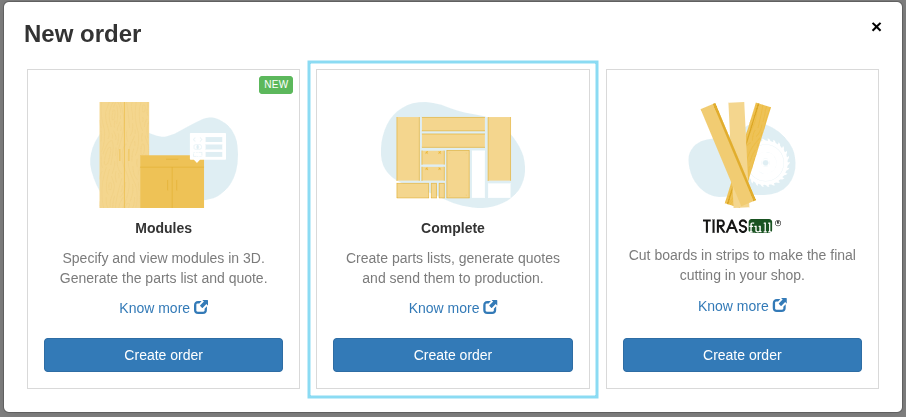

- Start a new service by choosing the "Complete" option

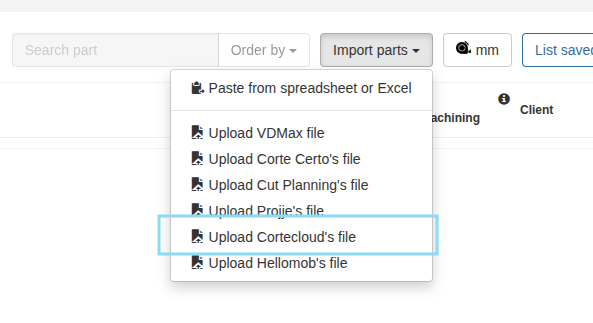

- Use the part import with the "Load Cortecloud file" option

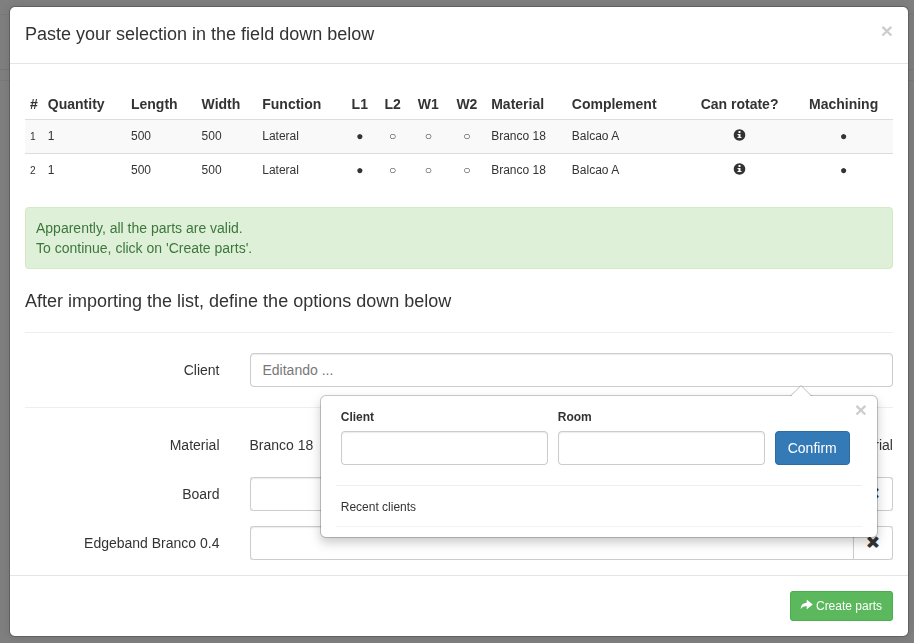

- After loading the file, the material linking interface will be displayed

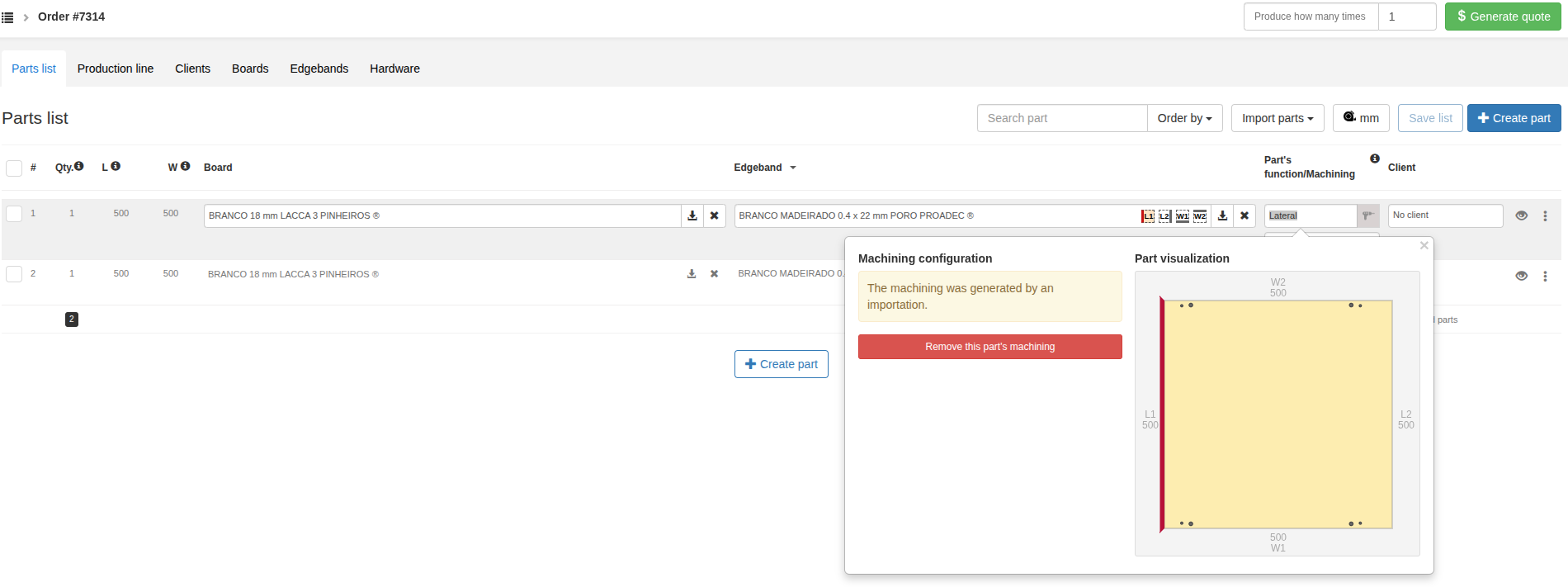

- After creating the parts, you can check the imported information, including the visualization of drilling quotas on parts that have machining data in the imported file

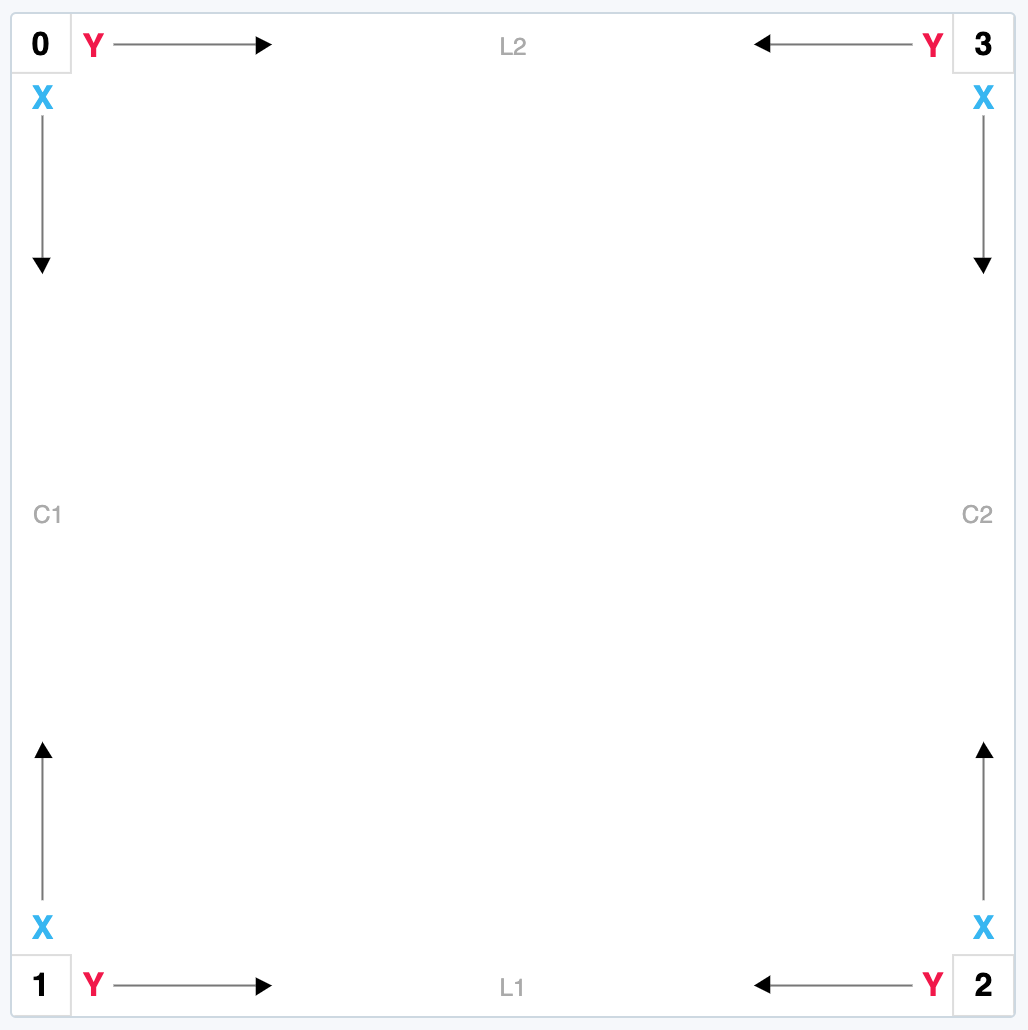

Part coordinate system

- Corners 0, 1, 2, and 3

- X and Y axes

- Sides C1, C2, L1, and L2

- Segments 0-1, 1-2, 2-3, and 3-0

JSON data structure

{

"parts": [

{

"quantity": 1,

"c": 500,

"l": 500,

"function": "Lateral",

"complement": "Balcao A",

"c1": "Branco 0.4",

"c2": null,

"l1": null,

"l2": null,

"material": "Branco 18",

"machining": {

"x": 500,

"y": 500,

"z": 18,

"startSide": 0,

"horizontalDrills": [

{

"corner": 2,

"direction": "XP",

"x": 0,

"y": 69,

"z": 10.5,

"depth": 24,

"diameter": 8,

"face": "i"

},

{

"corner": 1,

"direction": "XP",

"x": 0,

"y": 37,

"z": 10.5,

"depth": 24,

"diameter": 8,

"face": "i"

},

{

"corner": 1,

"direction": "XP",

"x": 0,

"y": 57,

"z": 9,

"depth": 22,

"diameter": 8,

"face": "i"

},

{

"corner": 2,

"direction": "XP",

"x": 0,

"y": 89,

"z": 9,

"depth": 22,

"diameter": 8,

"face": "i"

},

{

"corner": 3,

"direction": "XP",

"x": 0,

"y": 69,

"z": 10.5,

"depth": 24,

"diameter": 8,

"face": "i"

},

{

"corner": 0,

"direction": "XP",

"x": 0,

"y": 37,

"z": 10.5,

"depth": 24,

"diameter": 8,

"face": "i"

},

{

"corner": 0,

"direction": "XP",

"x": 0,

"y": 57,

"z": 9,

"depth": 22,

"diameter": 8,

"face": "i"

},

{

"corner": 3,

"direction": "XP",

"x": 0,

"y": 89,

"z": 9,

"depth": 22,

"diameter": 8,

"face": "i"

}

],

"verticalDrills": [

{

"corner": 2,

"bolthole": false,

"x": 25,

"y": 69,

"depth": 12,

"diameter": 15,

"face": "i"

},

{

"corner": 1,

"bolthole": false,

"x": 25,

"y": 37,

"depth": 12,

"diameter": 15,

"face": "i"

},

{

"corner": 3,

"bolthole": false,

"x": 25,

"y": 69,

"depth": 12,

"diameter": 15,

"face": "i"

},

{

"corner": 0,

"bolthole": false,

"x": 25,

"y": 37,

"depth": 12,

"diameter": 15,

"face": "i"

}

],

"furrowMachining": {

"face": "i",

"depth": 8,

"width": 6.7,

"distance": 15

},

"furrowMachiningPair": null

}

}

]

}

Example files and cases for import and expected results can be accessed through the Serrabits Google Drive directory

Attributes for drilling and machining

horizontalDrills: Configuration block for the list of horizontal (top) drills of the part.

-

verticalDrills: Configuration block for the list of vertical (face) drills of the part. -

startSide: Applies a 90º rotation to the entire machining of the part, can receive values 0 or 1. If 0 keeps the original machining, if 1 applies a 90º rotation. -

direction: Defines the orientation of the horizontal drills (on the top of the part), can receive values XP or YP. Simplified, if the drill is on segments 1-3 or 1-2 (L2, L1) the drill is XP, otherwise it is YP. -

corner: Defines the reference corner for the X and Y measurements of the drills, can receive values 0, 1, 2, or 3, applicable to vertical and horizontal drills. -

x: Defines the position of the drill on the x-axis of the part, applicable to vertical and horizontal drills, and must be set to 0 for horizontal drills with direction XP. -

y: Defines the position of the drill on the y-axis of the part, applicable to vertical and horizontal drills, and must be set to 0 for horizontal drills with direction YP. -

z: Defines the position where the horizontal drill will be in relation to the thickness of the part. It is only applicable to horizontal drills and it can receive any value within the thickness of the part. The position is considered from the internal face (front of the part) to the external face (back of the part), subtracted from the thickness of the part.Examples:

-

To place a horizontal drill in the center of the thickness of a part with 15 mm, z should be 7.5.

-

To place a drill 7.5 mm from the internal face of a part with 25 mm thickness, z should be 17.5 (25 - 7.5 = 17.5).

For horizontal drills, the value for

facemust always be "i". -

-

face: Applicable and required in all machining operations, can receive values "i" or "e", where i represents the internal face, and e the external face. -

bolthole: Applicable only to vertical drills, can receive the value true or false, representing whether the drill should be through (pass through the part) or not. Ex. assembly screws are through and should receive true, in addition to receiving the thickness of the part in the depth attribute. -

depth: Defines the depth for vertical drills, horizontal drills, grooves, and rebates. -

diameter: Defines the diameter of vertical and horizontal drills. -

furrowMachining: Represents the groove or rebate procedure on the internal face of the part. The width attribute describes the thickness that the groove or rebate will be made. The distance attribute describes the distance the groove should be made from the edge of the part. Both grooves and rebates are made on segment 2-3 (C2) of the part. In the absence of this procedure, the value should be null. -

furrowMachiningPair: Represents the groove or rebate on the external face of the part. It is applicable for dividers or shelves that have grooves or rebates on both sides of the part, has exactly the same data structure as furrowMachining, but the face attribute must receive the value "e". In the absence of this procedure, the value should be null.

We encourage testing the file loading in a service created with a Woodworking Professional account within Cortecloud, as after loading the JSON file, all machining can be visualized on the parts, making it easier to validate the data structure being developed.

Questions and additional information

Additional information, clarifications, and technical details about the import process with the JSON file should be sent to the email desenvolvimento@serrabits.com.br